Professional Zinc Plating

Industry-leading corrosion protection for automotive, agricultural and industrial components across North Texas.

Why Zinc Plating?

Zinc has been the workhorse of corrosion protection for over 150 years — and for good reason. When properly applied to steel, zinc sacrificially corrodes in place of the base metal, meaning it takes the hit from rust and oxidation while your underlying part stays pristine.

At Fannings Electroplating, we've spent nearly four decades perfecting our zinc plating process. We maintain strict bath chemistry control, proper cleaning and activation sequences, and quality checks at every stage. The result is a coating that not only looks great but performs reliably in the harshest environments.

From farm equipment exposed to fertilizers and moisture, to automotive parts that see road salt every winter, to industrial fasteners in humid warehouses — our zinc plating extends component lifespans and reduces replacement costs significantly.

Request QuoteZinc Plating Finishes

Clear Chromate

Bright, transparent finish that maintains the natural metallic appearance of zinc. Popular for automotive underhood components and visible hardware where a "bare metal" look is desired.

Yellow Chromate

Traditional gold-yellow tint providing excellent corrosion resistance. The industry standard for automotive, agricultural and hardware applications for decades.

Black Chromate

Sleek black appearance with good corrosion resistance. Popular for decorative hardware, firearms components and applications requiring a matte black finish.

Olive Drab

Military-spec green finish originally developed for aerospace and defense applications. Excellent corrosion resistance with distinctive appearance.

Zinc Plating Rates

Competitive pricing for production runs and custom projects. Volume discounts available.

Standard Zinc

- 0.0003" - 0.0005" thickness

- Clear, yellow or black chromate

- Standard turnaround (5-7 days)

- Basic inspection

Heavy Zinc

- 0.0005" - 0.001" thickness

- Enhanced corrosion resistance

- All chromate colors available

- Extended salt spray rating

- Detailed documentation

Production Run

- Custom thickness to spec

- Consistent batch quality

- Rush turnaround available

- Full certification package

- Dedicated account manager

Uses For Zinc Plating

Automotive

Brackets, fasteners, fuel system components, brake parts, suspension hardware, underhood brackets and clips, exhaust clamps, and restoration parts for classic and modern vehicles.

Agricultural

Implement brackets, fertilizer equipment parts, irrigation components, tractor restoration pieces, gate hardware and any equipment exposed to fertilizers and moisture.

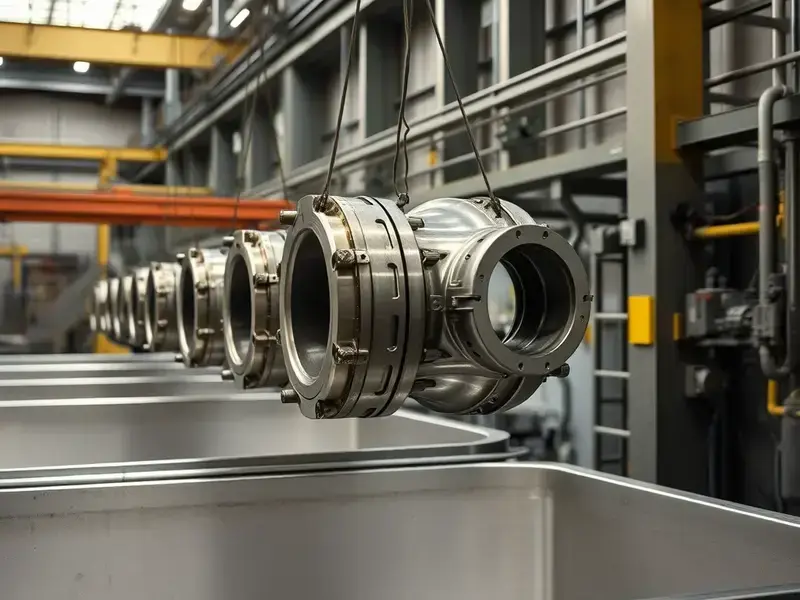

Industrial

Fasteners, bolts, nuts, washers, brackets, housings, valve components, pump parts and machinery components requiring corrosion protection in harsh environments.

Construction

Structural fasteners, scaffolding hardware, concrete form ties, bracing components and building hardware exposed to the elements during construction.

Quality Assurance

Every zinc plated part that leaves our facility has been inspected and tested. We don't guess about quality — we measure it.

Thickness Testing

We use XRF (X-ray fluorescence) and magnetic gauge testing to verify coating thickness meets specifications.

Salt Spray Testing

Sample parts undergo ASTM B117 salt spray testing to verify corrosion resistance ratings.

Visual Inspection

All parts are visually inspected for coverage, adhesion, finish quality and defects before packaging.

Need Zinc Plating?

Get a fast quote for your zinc plating project. Standard turnaround is 3-5 business days.